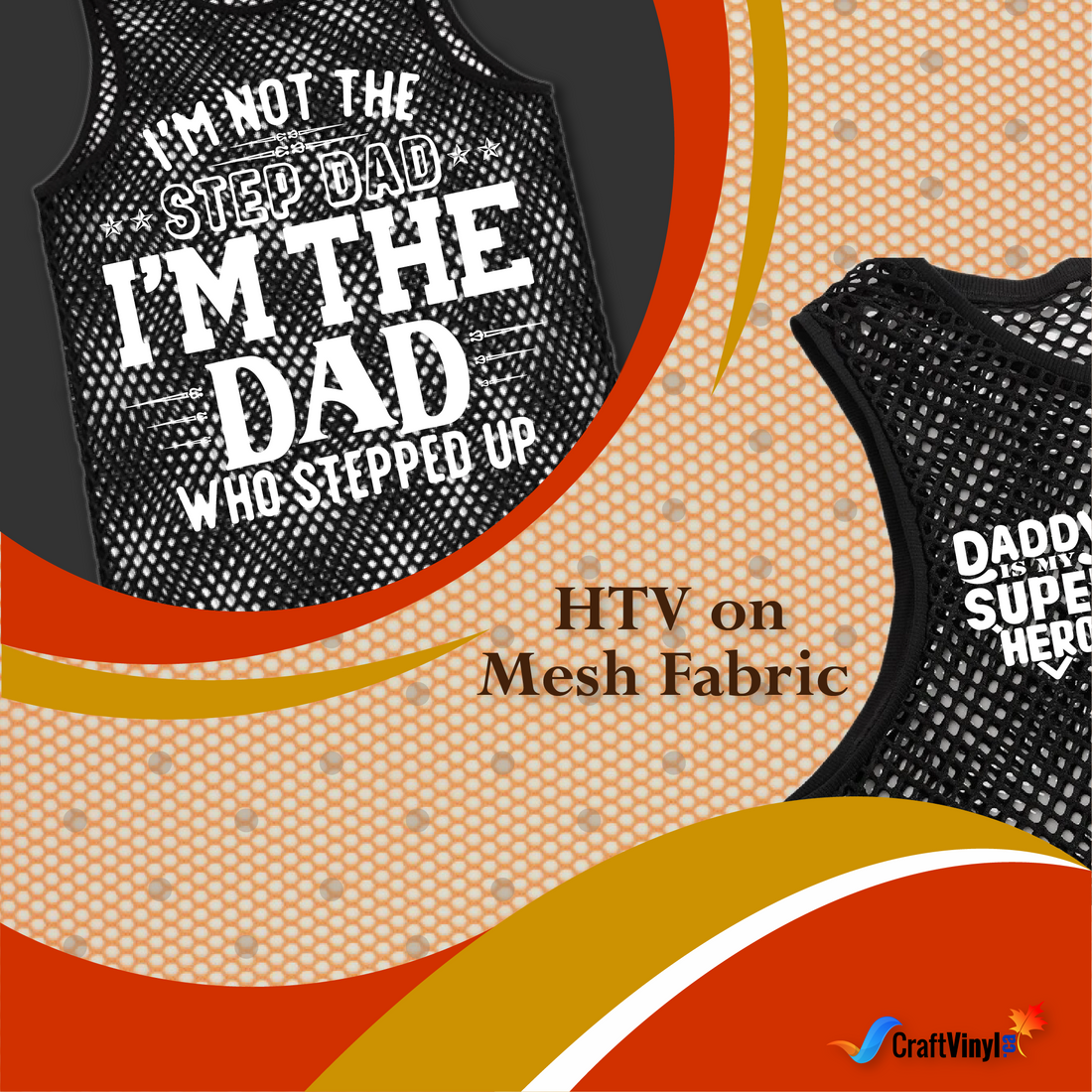

Applying HTV on Mesh Fabric!

Mesh can be a tricky fabric considering that it is composed of various materials, which may involve polyester or spandex. Aside from this, mesh clothing garments contain small or big holes that can also be seen in jerseys, making them a lot trickier to work with. But with these, it is possible to apply Heat Transfer Vinyl on mesh fabric.

Before we start with the application process, we must examine the mesh fabric we’ll be using before selecting the appropriate materials. Below, we have a list that can help you decide which HTV is the best for your craft.

Things to consider when working with mesh:

1. The materials used

Mesh garments can contain spandex, polyester, and such. This is when our choice of HTV comes in. An example would be when working with mesh jerseys that have spandex, make sure that the HTV could keep up with the garment’s flexibility. You can found this information in the clothing tag.

2. How to color garments?

You can dye garments through the process of sublimation. This process involves the usage of hot temperatures to transfer color. Applying vinyl that requires heat can be very bad for the garment as the temperature can cause movement in the dye, leading to a process called dye migration. Dye sublimation is often performed on fabrics like polyester.

If all the things were considered, we could safely proceed to the materials you’ll need to apply HTV on a mesh.

Materials:

- Heat Press

- Cutting Machine

- Weeding Tools

- Heat Transfer Vinyl

- Cover Sheet

- Heat Transfer Pillow (Optional)

The materials needed for this craft are similar to most heat transfer vinyl projects. Although you can also use a household iron, a heat press is preferable as it gives you much better control over the product. With uncertain temperatures and uneven pressure, using iron can lead to higher risks of damaging the product.

The HTV you’re using will depend on the fabric you have, as mentioned, stretchy HTV for mesh clothing articles containing spandex and HTV with dye block when working with garments containing a large percentage of polyester.

Another alternative for working with dye sublimated products is to use HTV with solid and bold colors like black. And using these colors would mean that even if the dye bleeds through, it won’t show.

You can use a heat transfer pillow for the inside of the item; however, you can replace this material with an extra cover sheet. A cover sheet can be thin tea towels, kraft paper, Teflon sheet, or baking paper. The sole purpose is to prevent direct contact between the heat press and the garment. It also protects if the dye begins to seep through and bleed.

Failure to use a cover sheet may lead to the adhesive melting through the holes of the mesh, creating a seal between the top and the bottom layer of the t-shirt, making it unwearable. It can also create texture on the other side of the shirt.

Steps in using HTV on Mesh:

1. Cut and Weed your design.

2. Insert a cover sheet or the heat transfer pillow inside.

3. Apply the second cover sheet on top of the garment itself.

4. Conduct a test press.

A test press can help eliminate the moisture trapped inside the shirt. In addition, it can also remove wrinkles which can help the vinyl adhere better; and support in terms of setting the correct pressure needed. This usually lasts between 1-3 seconds.

5. Remove the cover sheet above and apply the HTV.

6. Press for the indicated amount of time.

That would be all! We can check the instructions to see if the HTV is a cold peel or a hot peel. Again, follow the directions indicated for the best possible result. The HTV should completely adhere to the fabric if you only do one layer.

Applying HTV on a mesh is not limited to just one layer of vinyl. You can layer various colors with a few modifications on the steps listed. One, you should apply the base or the first layer in a shorter amount of time. Like the test press, the first layer should be pressed on for about 1-3 seconds.

You can use a squeegee in any case that the HTV begins to peel off with the carrier sheet. You can also use your fingers to push the HTV back down and prevent it from peeling away. It is important to note that lifting is regular as the HTV was not given enough time to activate. Next, apply the second layer and use the appropriate time required. This way, they melt at the same time and adhere.

If you’re planning to apply HTV on the front and the back of the t-shirt, remember to give it a few minutes to cure before doing the other side. This way, we don’t stress the vinyl or the fabric.

Another thing you might encounter would be the heat transfer pillow or the cover sheet sticking to the garment itself. This is normal as the mesh spaces allowed the vinyl to melt through and stick to it. If this happens, remove it as soon as possible, as leaving it on can lead to tears and ripping in the vinyl.

With all the information disseminated, we hope you learned something from this blog! If you did, you could always share it with your fellow vinyl crafters!

Made any craft with heat transfer vinyl or adhesive vinyl? Simply send us a direct message or tag us! You can send us a message on the listed social media sites to get featured on our page.

Social Media Accounts:

FB: CraftVinyl.ca

IG: CraftVinyl.ca

TikTok: craftvinyl.ca

You can also check our online shop at www.craftvinyl.ca for your heat transfer or adhesive vinyl needs. With that, have safe and happy crafting, Crafters!

Discover More Great Articles On Crafting

Check the links below for more exciting vinyl projects.

HEAT TRANSFER VINYL TO LEATHER